Five Light Shaping Diffuser® Use-case Scenarios for Spatially Variable Micro-Optics

Most of Luminit’s light shaping materials are considered spatially uniform optics where a single micro-structure is repeated over the entire surface of a large sheet. A spatially uniform optic has full coverage of a single diffuser such as a 60deg Light Shaping Diffuser across the entire surface of the optic. A spatially variable micro-optic, however, functions similarly to a Fresnel lens where the optical micro-structure varies across the part. These micro-optics can have collimating, focusing, or diverging optical power. The following use-case scenarios are examples of how a spatially variable micro-optic provided the best results.

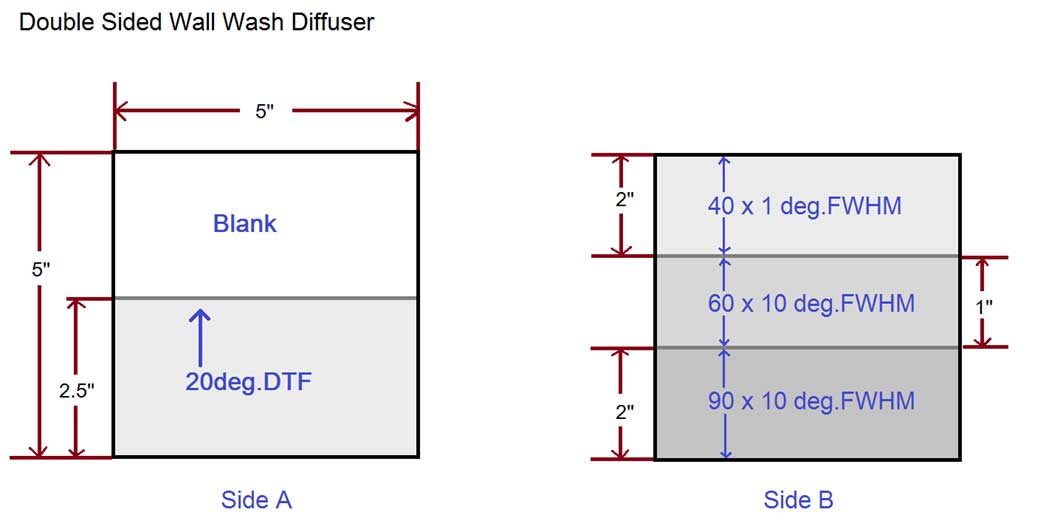

Use Case 1: Wall Washing

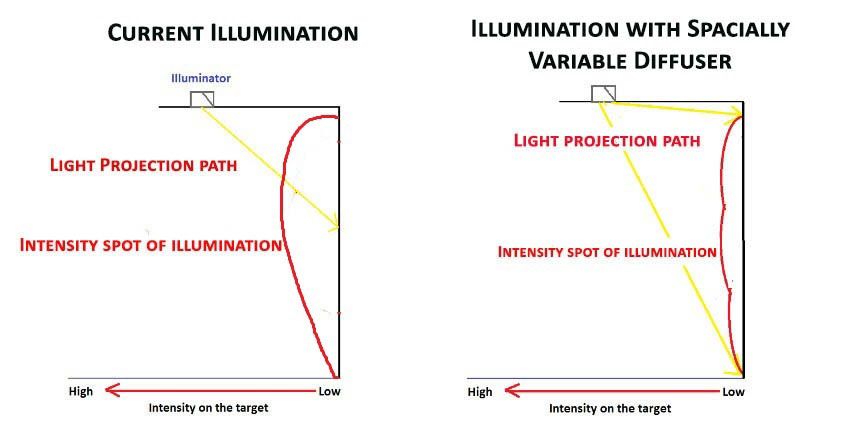

The first LED light diffuser use-case scenario is what we coined as the “true wall wash” application. Many recessed down lights or track fixtures mounted on a ceiling use a secondary optic over the LED to collimate the light with a Light Shaping Diffuser or Directional Turning Film at the exit surface. The light fixture is closest to the top of the wall being illuminated, and the distance to the ground level of the wall is further, resulting in more light at the top of the wall. Luminit designed a spatially variable Light Shaping Diffuser with a large diffuser angle (60° FWHM) on the top section of the film and a smaller (10° FWHM) diffuser angle on the bottom of the single film. The unique light shaping material resulted in a more uniform illumination up and down the wall, as well as a soft lit appearance on the top of the wall without wasting the collimation to achieve the light throw on the bottom section of the wall. Wall grazers are another application that can use this optical diffuser technology with the same principle.

Use Case 2: Large Sources

In general illumination, we have had requests where the input light is non-uniform because the source is large. A standard light beam shaper may homogenize and mix the light to a certain amount, but this could be greatly improved with a spatially variable diffuser. If there is a section of the large source that has a stronger output compared to the other areas, a larger beam angle can tune the stronger output. The custom spatially variable diffuser can have a different beam angle prescription in areas that match in input to increase the uniformity and beam control.

There are many ways to construct spatially variable light diffuser film. A cost-sensitive application may be able to tolerate small seams between each beam angle. In a step and repeat fashion, areas of different diffusion angles can be overlapped with seams <1mm on a single substrate.

Use Case 3: Exterior Automotive Lighting

Seams between each optical prescription are often not acceptable for applications such as exterior vehicle light diffusion where lenses can have 3D shapes and compound curvatures. To optimize a Day Running Light (DRL), for example, we could have applied a standard uniform optic with an elliptical beam angle. However, to maximize performance, we used a six-axis robot that gradually changes the beam angle across the entire part, resulting in a lens with a smoothly varying diffusion angle. By following the shape or contours of the lens with an elliptical beam angle, we were able to create a DLR that is beautifully homogenized at every angle.

Another case involved an “S-shaped” lamp where the LEDs followed the shape. While a secondary optic could have been used to collimate the light output, the LEDs still needed to be homogenized. We suggested a spatially variable elliptical beam angle where the large beam angle follows the shape of the LEDs and a small beam angle in the opposite orientation to keep the collimated beam intact. This method increased the uniformity and maximized the system performance so the most lumens reached the target and the collimation stayed intact.

.

Use Case 4: Head Up Displays (HUDs)

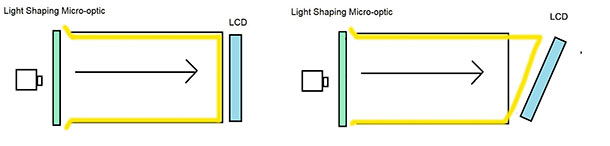

In this case, a top hat diffuser (aka flat top) was suggested in order to get a sharp cut off at the tail and a flat top distribution in the center. The optic was used to homogenize an LED source and expand the beam to cover a TFT display in a HUD application. Light Shaping Diffusers produce an intensity pattern that is best described by a Gaussian distribution due to the specific recording process that creates a certain side wall profile in the micro-structure. Gaussian distributions place the most amount of light in the center with a gradual fall off on the tails of the profile. Light Shaping Micro-Optics, however, create non-Gaussian profiles using grayscale lithography that provide “deterministic” profiles such as a top hat light distribution. This alone would have been ideal if the optical train were perpendicular and everything aligned; however, this was not the case due to volume constraints under dash when packaging a HUD unit. To have an asymmetric resultant distribution, the spatially variable micro-optic illuminated the TFT evenly when the optic is off axis from the display. Grayscale lithography has the capability of prescribing a variable lens with high resolution due to the recording spot size of 400×400 nanometers. Just like the spatially variable Light Shaping Diffuser, the top section of the optic had a different beam angle prescription than the bottom half with the only difference being the profile shape was top hat instead of Gaussian.

Use Case 5: Laser-based HUDs

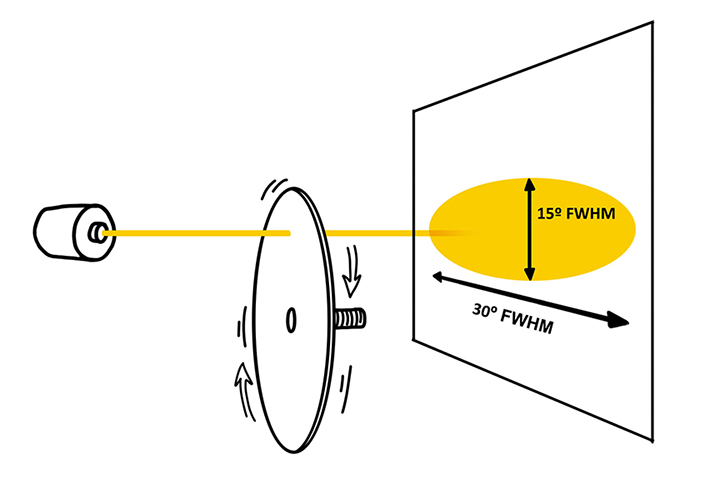

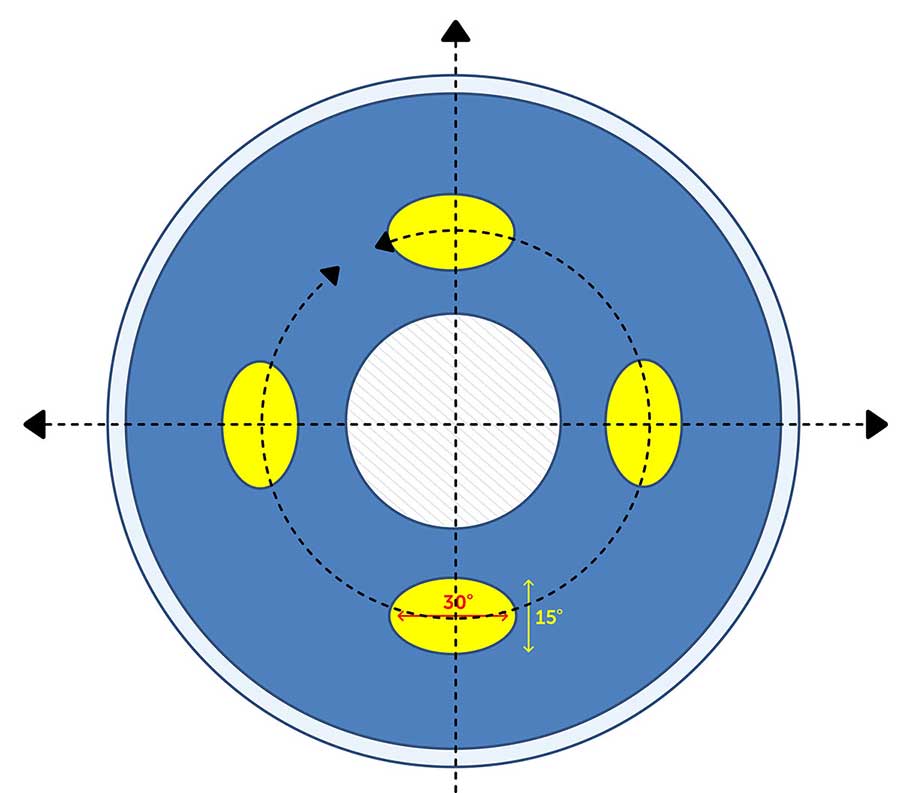

Laser-based HUDs have an added level of importance for the flat optic which is to de-speckle the light source. Speckle is caused by coherent light sources interfering and creating random dark and light areas in the beam. This can be reduced by oscillating or rotating a Light Shaping Diffuser or Light Shaping Micro-Optic in front of the source. The most common method for de-speckling a laser for a HUD is rotating the optic because of the mounting constraints. The ideal beam angles for the HUD would be elliptical (i.e., 20°x10° or 30°x15° FWHM) because of the rectangular display; however, this is not usable as a static prescription when the diffuser rotates. In this case, a spatially rotational elliptical diffuser was needed to optimize the light. A recording of the elliptical beam needed to be in place to keep a static elliptical profile as the diffuser spins. This was accomplished using the 6-axis robot and/or grayscale lithography.

|  |

Figure 7: A spatially rotational elliptical diffuser optimized the light of laser-based HUD and can be accomplished using the 6-axis robot and/or grayscale lithography.

The above use-case scenarios are just a few examples of how spatially variable Light Shaping Micro-Optics were used to overcome difficult optical challenges. Our in-house direct-writing of masters bring custom micro-optics designs from conception to high volume production. Top hat top intensity profiles can be manufactured by injection molding, roll-to-roll embossed, or sheet-by-sheet embossed depending on thickness, temperature, and volume requirements.

Considering the current state of the world, using Luminit spatially variable micro-optics solves two problems: first, a fully-customizable range of effects can be achieved with fewer parts increasing the efficiency of the parts already in the design, and second, Luminit products are made in America, which means fewer interruptions in the supply chain due to shipping delays.

Reach out to us at sales@luminitco.com to learn more about our light beam shaping micro-optics.