Advances in Surface Relief Flat Optics

By Anthony Silvestris

It’s a good time to be in optics but an even better time to be in microoptics. Growth areas such as LiDAR, Time of Flight and 3D sensing are supported by advanced optical components including surface relief flat optics that provide customized intensity profiles and beam shapes. Luminit has made significant advances in this area with Light Shaping MicroOptics (LSMs), an in-house direct-beam laser writing platform. Using greyscale laser photolithography, this is a single-step, maskless writing process that enables the creation or mastering of refractive and diffractive optics with small feature sizes. With design, mastering, replication, test and measurement under one roof, advantages for customers include faster time to market and simplified supply chains. Thin film or rigid optical components can be manufactured by injection molding, roll-to-roll embossing, or sheet-by-sheet embossing, depending on thickness, substrate, temperature and volume requirements.

LED Light Shaping Beyond Gaussian

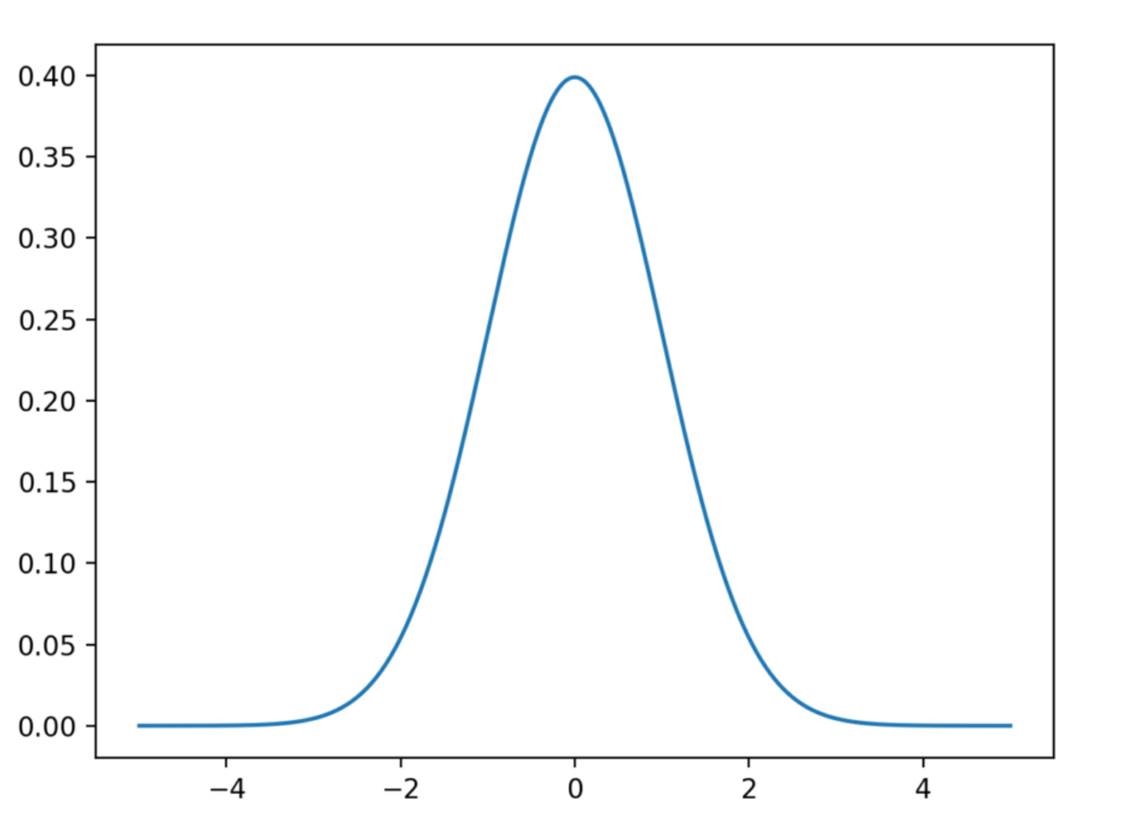

Most diffusers create Gaussian or bell-shaped intensity profiles. In certain applications, other intensity profiles like flat-top, batwing, random dots, and structured light are more ideal for system efficiency or sensitivity. The current methods of fabricating surface relief flat optics include holographic, E-beam, diamond turned and grayscale lithography. Each of these methods has advantages that depend on the application or industry.

Luminit Light Shaping Diffusers use surface relief micro-structures that rely on simple optical refraction to increase the divergence angle of the source. The precise beam angle control and uniformity of this type of diffuser is particularly useful for the LED industry where the ability to manipulate the Full Width Half Maximum (FWHM) of the light and improve the homogeneity of the projected beam allows OEMs flexibility without sacrificing the efficiency of a system. However, because a holographic diffuser has a Gaussian profile, it is not necessarily suitable for applications such as 3D sensing and LiDAR where the intensity profile and shape need to be customized to improve the efficiency of the system. These applications require custom microoptics that can be manufactured using our LSM platform.

|

|

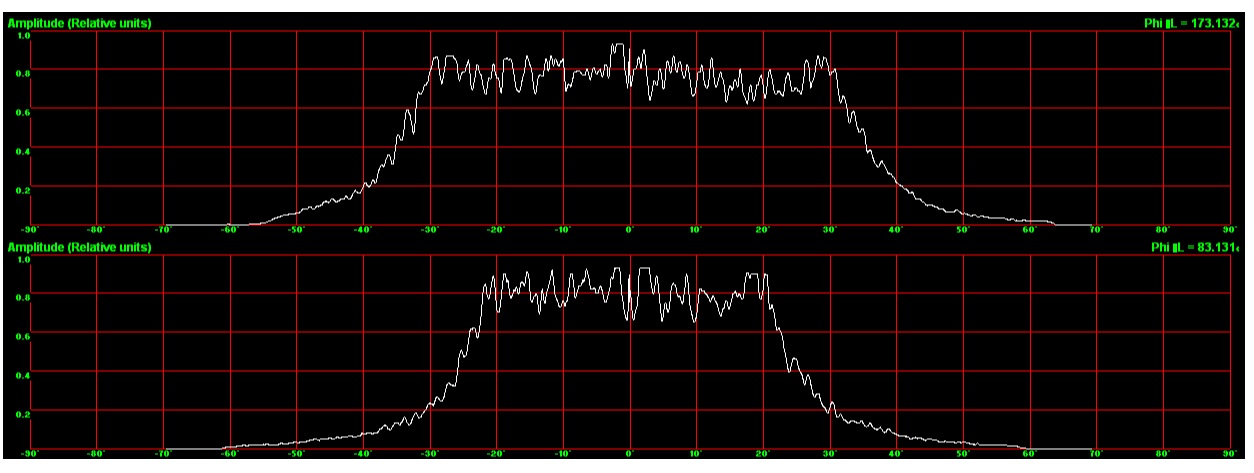

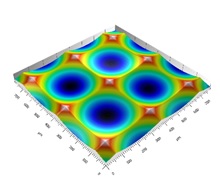

The same is true in 3D sensing applications where the illumination plane (a flat field) needs to be uniformly illuminated with sharp drop offs on the edge. A Gaussian intensity profile has higher intensity in the center of the profile with gradual drop offs on the edge. With Light Shaping Microoptics, however, an array of custom micro lenses is created with grayscale lithography one lens at a time. Advantages include smaller features sizes (down to 1 micron), higher resolution and a more uniform output across the field of illumination.

Although LSM can control the intensity profile with similar performance as Light Shaping Diffusers, it does not replace this technology because a fair amount of customization is required and there are size limitations when compared to LSD. However, Luminit LSM uses a maskless process so level write times are much faster than a multi-level writing process, and we can produce 200mm x 200mm size parts. For larger sizes and mass production, Luminit can take this master and make a larger part using an in-house technique of stepping and repeating.

In the automotive optical space, large diamond-turned structures are used to control the light output, which allows OEMs to meet strict regulations. The downside is the lens arrays are large (0.5mm) and cosmetically unappealing. LSM can make the same lens shape and shrink the size of the features. This works because a lens does not have to be 0.5mm to be refractive with a white source. Depending on the lens function, the size can be as small as 10 microns, which is invisible to the eye, making the appearance smoother and homogenous without losing the lens function.

LSMs Are Ready for Mass Production

Luminit’s mass-production capabilities, specifically in roll-to-roll and injection molding production, allow us to scale the final product to high volume. Since LSM production is compatible with these standard processes we set up for LSD, the cost is comparable. We’re finding that glass, roll-to-roll, and even injection molding manufacturing methods produce high quality optics for LIDAR and other precision-based technolgies at similar manufacturing speeds and with similar throughputs.

While Light Shaping Microoptics may not apply to every application, it certainly widens our customers’ design windows and allows them to differentiate their offerings to their markets. For more information, contact sales@luminitco.com.