Preserving Polarization for Display Applications with Luminit Diffusers

By Richard Cordero

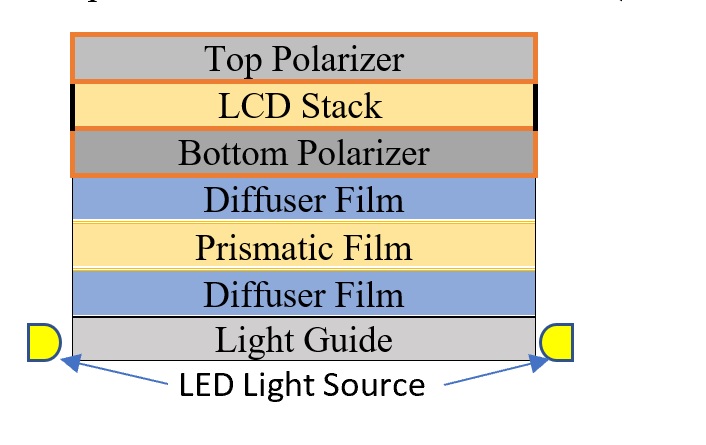

Liquid Crystal Displays (LCDs) have dominated the display market with their long service life, power efficiency, and low market price and are commonly used in flat-panel computer monitors, TVs, notebook computers, mobile phones, navigation systems, and many other video display consoles. In the LCD display stack, a custom light diffuser plays an important role in the backlight unit, which consists of a stack of multiple optical films that deliver the source light (LEDs) towards the LCD panel.

Properties required of these diffusers include high transmission efficiency as well as the ability to homogenize a light source and preserve polarization (i.e., non-birefringent).

What Is Birefringence?

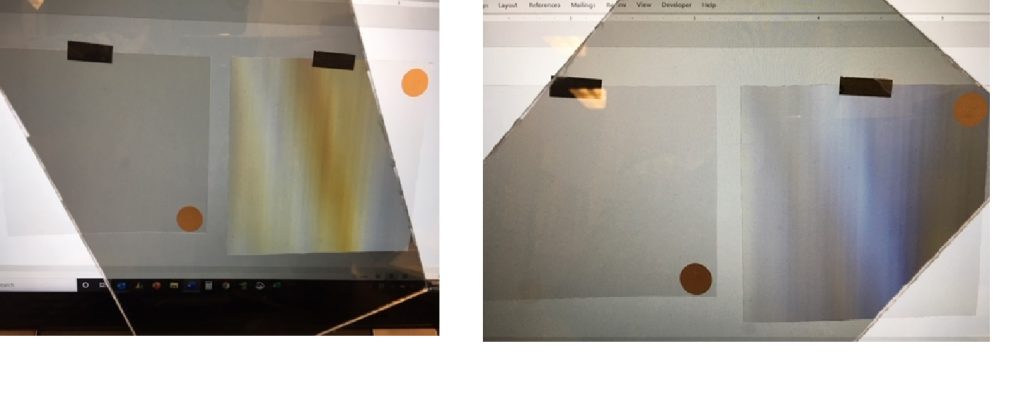

Birefringence is the optical property of a material having a refractive index that depends on the polarization and propagation direction of light. It can create a number of optical artifacts in a display like Newton’s rings and moiré. LCDs only transmit a specific polarization orientation when active, and discoloration can occur if there is any material in the film stack that changes the polarization of the light. An effective way to prevent this phenomenon is to use low birefringent material in the stack; however, many OEMs do not realize this until they experiment with different films and start to see visual artifacts in the display.

An easy test to see if a material has birefringence is to wear polarized sunglasses and rotate a material in front of an LCD display. If the material does not have low stress in the composition, you will see it go from light to dark with color distortion as the material rotates.

Reducing Visual Stress with Light Shaping Diffusers®

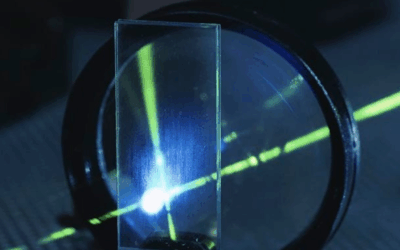

Luminit’s Light Shaping Diffusers® use a surface relief, pseudo-random microstructure that has high transmission efficiency (80% to 92%) and utilizes the photons efficiently to achieve high homogenization with minimal light loss. Luminit diffusers are produced on a low birefringent PC substrate that helps preserve polarization in the optical stack.

Most polymer films are extruded, which induces stress on chemical composition when the polymer molecules form. This is because the extrusion process is pulling the polymer from a B stage (semi solidified stage) into a thin profile. These films will have birefringence in one axis as it is a linear process with single strands of monomers connecting along the single axis.

It is impossible to achieve zero birefringence, but it can be mitigated by reducing stress. Luminit and other thin-film optical manufacturers that use these base polymer substrates can add their technology to the surface to manipulate the light output if it is a cast post process. The cast and cure techniques allow the manufacturer to print a microstructure on the surface without implementing any additional stress to the material as the resin is deposited and forms a lens through a U.V. curing process.

Low stress allows the two-part optical solution to have a homogeneous output when polarized light transmits through the material. Luminit’s Light Shaping Diffusers® can help minimize light loss as well as maintain polarization in the optical stack.

Luminit is an industry leader in manufacturing light diffuser and offers a broad selection of efficient light transforming products. Luminit offers the widest selection of competitively-priced LED light diffusers and other optical diffuser products.

Learn more by contacting sales@luminitco.com